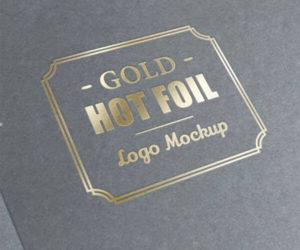

1. Hot Foil Stamping

Hot foil stamping is also called hot pressing transfer printing, foil stamping machines uses heat to transfer metallic foil to a solid surface. Hot silver, hot metallic s by means of a certain pressure and temperature of the metal foil to the printed matter on the method. >>Read more

Hot foil golden also called metallic process Hot Foil Rose Gold proess

2. UV coating

Ultraviolet cured coatings can be applied over ink printed on paper and dried by exposure to UV radiation. UV coating can be applied via most conventional industrial coating applications as well as by silkscreen.

Features: A printed page with UV coating applied can be very shiny or flattened to a matte finish. Read more>>

ink printed on paper dried by exposure to UV radiation

3. Embossing & Dembossing

Embossing and Dembossing are the processes of creating either raised or recessed relief images and designs in paper and other materials. Divided into cheap ordinary corroded version and expensive laser relief version of the two.

- Pressure: the intensity of the impact on the weight of the stock being embossed.

- Heat: the ability to maintain a consistent heat level for the best impression.

Application: Suitable for more than 200g of paper

Scope:handmade box, palettes,Books installed, envelopes, cover, desk calendar, high-end packaging, handbags and so on. >>Read more

4. Die Cutting

The die-cutting process is to produce a special die-cutting knife according to the design requirements of the printed matter, and then press the printed matter or other substrates under pressure to cut into the forming process.

Applicable : Above 157g of paper as raw material products, such as stickers, trademarks, gift boxes, related printing works of art. >>Read more

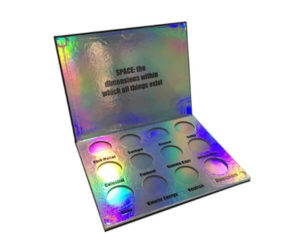

5. Glitter Process

Paper coated of glue, and then to the glue on the gold powder.

Glitter describes an assortment of small, colourful, reflective particles that comes in a variety of shapes .Glitter particles reflect light at different angles, causing the surface to sparkle or shimmer. Glitter is like confetti, sparkles, or sequins, but somewhat smaller. Used for paper box , paper bags, paper palettes and gifts. >>Read more

6. Glossy & Matte Lamination

Definition: The plastic film covering the surface of the printed matter, and the use of adhesive by heating, after pressure to bond together to form a paper, plastic one of the print processing technology.

Features: Glossy lamination products on the surface of the bright, strong performance, and more for the product category printed matter. Matte lamination is not reflective on surface. >>Read more

7. Flocking

Flocking is the process of depositing many small fiber particles (called flock) onto a surface. It can also refer to the texture produced by the process, or to any material used primarily for its flocked surface. Flocking of an article can be performed for the purpose of increasing its value in terms of the tactile sensation, aesthetics, color and appearance. >>Read more

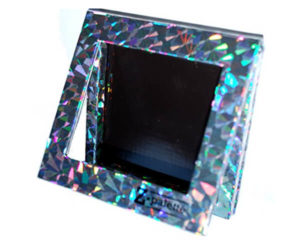

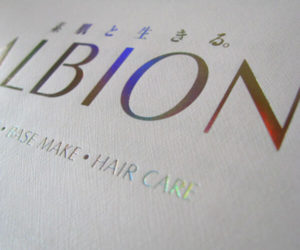

8. Holographic Process

Holographic silver is a bit like the back of the disc that clock “laser color”, with the viewing angle is different, showing a red and blue gradient. The ordinary silver is reflective silver. >>Read more